Dealing with variable demand but with fixed capacity.

One of the biggest challenges facing HIM Directors and CFOs is the need to balance fixed internal coding production capacity with “lumpy” and variable coding demand.

They must often make a choice between having enough coders to handle peak volumes, or staffing for an average volume and accepting that on some days bills will be dropped a few days later while the fixed production capacity catches up with the backlog.

This is not a rare occurrence. Chart inventory is statistically highest on Mondays and Tuesdays, but then drops sharply over the rest of the week. So, how does the HIM director cope? By increasing the fixed costs (salary, tax, and fringe) and staffing at a level to drop bills within one day even on the busiest days? Or let the Friday afternoon discharge bills drop on Wednesday, delaying cash in the door?

Further complicating this issue is the impact of the inevitable unexpected resignations, unplanned leaves, peak vacation months, and just plain old sick days. If your internal coding team is very large, say 50+ coders, you may be able to manage these events internally by paying overtime, but this further increases your costs. If you have a lean team of 10 to 20 coders, it becomes a much bigger challenge. Also, coders tend to specialize in one type of coding (such as IP or ED). If you have two ED coders and one quits you have just lost 50% of your ED coding production capacity.

The final complicating factor (which also impacts the HIM Directors) is the scarcity of experienced coders.

Demand far exceeds availability in this sector. Coders know this and often demand high salaries and other perks.

Achieving a “coding Utility Model”

Vee Healthtek has developed a solution that allows HIM Directors and CFOs to obtain coding production in a way that is very similar to how they obtain electricity or water

That is to say, capacity that increases or decreases nearly on demand to meet production requirements, coupled with a cost model that ensures you only pay for what is consumed.

The foundation for achieving a coding utility is choosing a partner with enough coding production capacity to accommodate variable demand automatically or on very short notice. Your partner must also link this variable capacity to a cost model that charges per-chart fees rather than a per-man-hour or monthly FTE fee. The per-chart cost model ensures that you only pay for charts coded and not for idle resources.

Your coding partner will need a baseline of production volume in order to start and keep the utility running in tune with your procedures and policies. A coding partner can easily vary production to meet demand between 80% and 120% of a baseline production level.

It is much more difficult and requires much more time to start production from zero, because your partner will not have coders assigned to your hospital and will not be in tune with your systems. So, to keep the coding utility running, the HIM Director should allocate at least 20% of the coding production to the coding partner and retain the balance in house.

The actual split of baseline production for your facility would be determined by considering the total chart volumes and any particular internal coding constraints.

How it works:

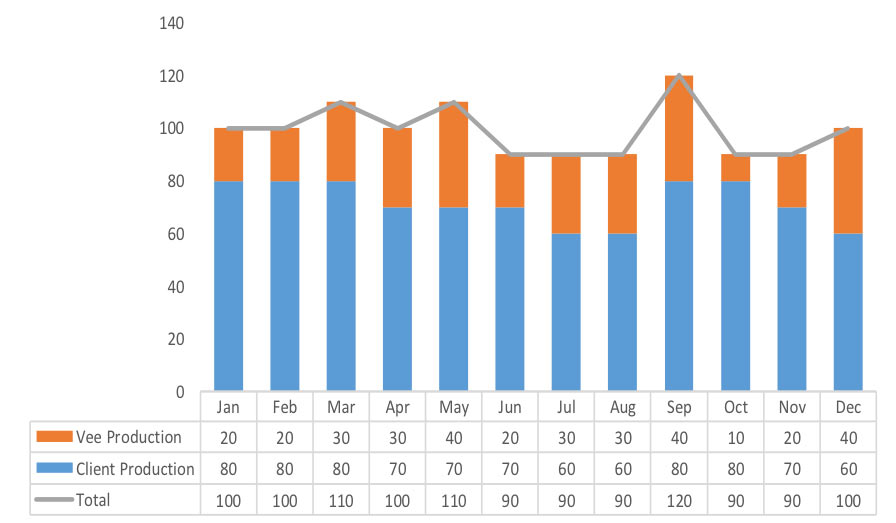

Perhaps the best way to show the benefit of such an arrangement is by following the coding demand and production levels of a typical client over the course of a year – as represented by the graph below.

The vertical axis and the gray horizontal line represent coding demand in percentages, with 100% being the typical monthly average. The graph indicates that over the 12-month period total demand varied between 90% and 120% of the average month.

The blue and orange bars show what percentage of the demand was addressed by the in-house coders, and what percentage by Vee Healthtek.

At least 20% of the average demand has been allocated to Vee Healthtek to build and keep the coding utility running and efficient.

Over the 12-month period, you can also see what would happen if from April to June the HIM director lost 10% of internal capacity due to a coder medical leave. In this scenario, Vee Healthtek increased its production to make up the shortfall, even in months like May where overall demand increased to 110% of the average.

Also shown on the graph is a drop in in-house production during the high vacation and holiday months of July, August, November, and December.

In each of these months, Vee Healthtek has metered its production to address the variable of lower in-house production and higher or lower overall demand.

All of this takes place automatically or with little more than a quick email to the Vee Healthtek coding manager indicating that more production will be needed. Coding quality is ensured, and the HIM Director only pays for the charts actually coded.

Conclusions

Realizing a “utility-like” delivery model has been the Holy Grail for many corporate processes including IT, accounting, and HR/Payroll functions.

The reason for this is the unique benefits that are realized in such a model, such as:

- Transforming a highly fixed cost process to a more variable cost model.

- Having on-demand capacity to meet the variable demands of the business.

- Optimizing internal costs so that there is a direct link between costs and actual production delivered.

For coding, the HIM Director and CFO realize all of the above benefits, plus additional ones due to the unique environment of coding. They include:

- Increased cash flows by having bills dropped faster.

- Reduced HR recruiting and retention costs.

- Access to Vee Healthtek’s best practices, learned from working with a diverse mix of major hospital clients.

- Improved overall coding accuracy

All of this is possible without sacrificing any control over the core coding process. For any HIM Director or CFO, it is an opportunity well worth exploring.